Talk to our experts about your requirements

Powder filling machines come in a wide variety of shapes, sizes, filling principles and degrees of technical sophistication. All-Fill are at the technological forefront in the design of vertical auger powder filling machines. This represents a 95% volume of powder filling machines sold, the remaining 5% comprising; vacuum fillers, cup fillers and gravity fillers.

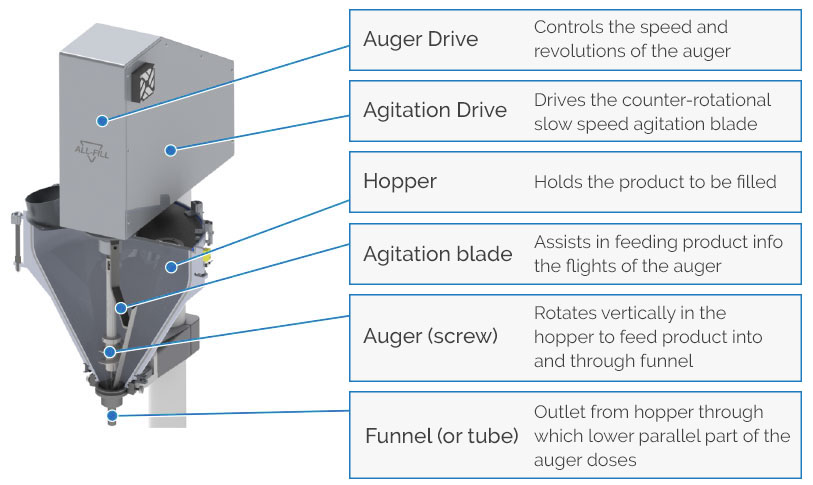

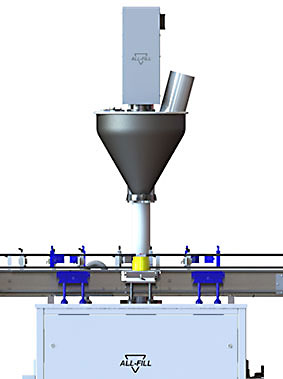

The principle of the vertical auger filling machine is very simple. The basic filling head comprises six primary components:

The auger drive rotates the auger at a constant speed to feed product out of the funnel. The agitation blade, separately driven and controlled, rotates in the opposite direction to the auger, de-aerating and homogenising the powder, and breaking any product bridge which can form in non-free flowing powders. The agitation blade extends down to the throat of the funnel preventing rat-holing and cavitation and ensures that the auger flights are consistently filled.

The lower parallel flights of the auger that sit within the funnel are precision machined so that each pitch has a precise volume. If an auger with flights of perfectly even pitch, evenly filled with powder of constant bulk density and even particle distribution, rotates a precise number of revolutions, theoretically there would be zero deviation in dose from one cycle to another. In most applications where these conditions more-or-less apply, volumetric filling is entirely appropriate and typically, accuracies in the range of ± 0.5% to 2% can be expected.

Where such factors as variations in bulk density and particle size/distribution, high cost, or criticality of dose demand closer tolerances, weigh-filling technology can be employed.

Before we look at the different types of tooling for different product characteristics, we first need to identify the type of product we are handling. There is a simple (but not completely foolproof) test for evaluating the flow characteristics of powders. If, when you insert a pencil into the top of a container full of power and then remove it, the hole immediately collapses in on itself, then the powder would be deemed to be free flowing. If, however, a perfect impression of the pencil remains, then it is deemed non-free flowing. Partial collapse might indicate a semi-free flowing powder.

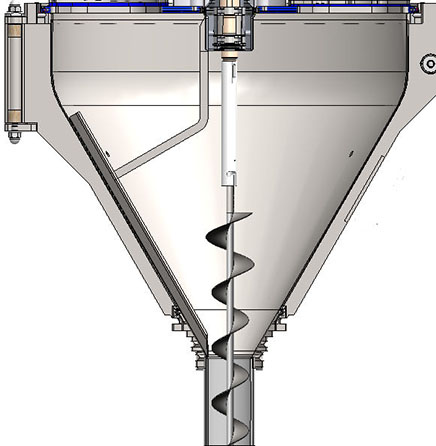

This diagram shows the tooling set-up where the auger is flush with the bottom of the funnel and the agitation blade extends into the throat of the funnel. The auger featured shows larger diameter “over-flights” in the hopper section. This pushes the otherwise reluctant powder downwards to the funnel throat where the agitation blade feeds the flights of the smaller diameter parallel section. The agitation mode can be controlled so that it stops between fills to avoid overworking and compacting the powder. If the powder is aerated coming into the hopper, the agitation mode can be changed to “continuous running” to assist with removal of the air. A larger hopper volume will aid de-aeration and homogenisation by allowing greater agitation/residence time.

A delicate or granular product might be damaged if large diameter compressive auger over-flights are used within the hopper section. In instances like this, an auger with parallel flights would be selected. Furthermore, a semi-free flowing powder might tend to dribble after the auger has stopped. In such cases, it is necessary to create a slight back pressure to retain the powder in the funnel by fixing a “drip washer” to the bottom of the auger, or adding a lip or crosswires/gauze to the bottom of the funnel. The correct solution varies with each powder.

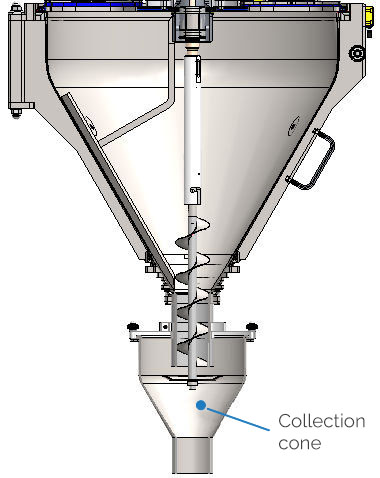

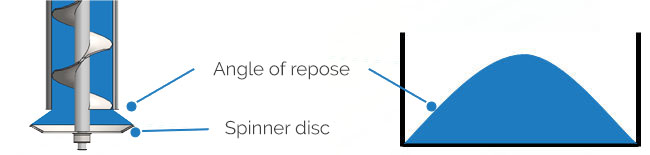

When free-flowing (granular) products are being filled, a method of cutting off the powder flow is required. The usual method is to use a spinner disc; a saucer-shaped disc attached to the end of the protruding auger, designed to retain the product flow. All powders have an angle of repose, the angle at which a collapsing heap of powder will come to rest rather than continue to spread outwards; the (top enclosed) angle for small smooth spherical beads for instance being much greater than for granulated sugar. The gap between the bottom of the funnel and the spinner disc is determined by the powder dosing rate, i.e. the gap needed to permit unrestricted product flow. The spinner disc is sized to prevent the powder trickling over the edge of the disc once the auger has stopped, taking into account this gap and the powder’s angle of repose. As the spinner disc throws the powder outwards, a simple collection cone funnels it down to an appropriate size. The spinner disc approach achieves a perfectly clean fill without expensive shut-off valves and complicated pneumatic/moving parts.

The size and type of the auger and funnel tooling is determined by a number of factors:

- fill weight

- dosing rate

- accuracy

- container neck opening

- product characteristics

A small auger and funnel means a slower fill speed but results in greater accuracy. Conversely, a larger auger will deliver product more quickly but less accurately. Where a wide range of fill weights are required, more than one tooling set may be needed to achieve the necessary combination of speed and accuracy.

Consideration must also be given to the size of container that is being filled. For clean filling, the bottom of the funnel should be positioned as close to the top of the container as possible. If the container neck opening is 5cm ID, the funnel needs to be sized accordingly.

Another factor that must be considered when choosing suitable tooling is the product characteristics. Non-Free-Flowing Powders like talc may require an auger with larger diameter “over-flights” to push reluctant powder downwards to the smaller parallel section. The agitation mode can be controlled so that it stops between fills to avoid overworking and compacting the powder and if the powder is aerated coming into the hopper, the agitation mode can be changed to run continuously to assist with removal of the air. A larger hopper volume will aid de-aeration and homogenisation by allowing greater agitation/residence time.

Semi-Free-Flowing Products (e.g. instant coffee powder) that are delicate or granular might become damaged if large diameter compressive auger over-flights are used within the hopper section. In instances like this, an auger with parallel flights would be selected. Furthermore, a semi-free flowing powder might tend to dribble after the auger has stopped. In such cases, it is necessary to create a slight back pressure to retain the powder in the funnel by fixing a “drip washer” to the bottom of the auger, or adding a lip or anti-drip grid to the bottom of the funnel.

When filling Free-Flowing Granular Products like table salt or granulated sugar, a method of cutting off the powder flow is required. The usual method is to use a spinner disc; a saucer-shaped disc attached to the end of the protruding auger, designed to retain the product flow. All powders have an angle of repose, the angle at which a collapsing heap of powder will come to rest rather than continue to spread outwards. The spinner disc is sized to prevent the powder trickling over the edge of the disc once the auger has stopped. As the spinner disc throws the powder outwards, a simple collection cone funnels it into the container.

All of All-Fill’s tooling (and hopper) is no-tools removable for ease/speed of change-overs and clean-downs.

When filling volumetrically, the amount of product filled into a container is dependent upon the number of revolutions made by the auger. This is the same whether filling semi-automatically or automatically, with one auger or multiple augers.

Volumetric fillers can be linked to a downstream check-weigher or weigh-cell to perform three important functions; provide weight data, reject under/over weights, and compensate for trend changes in powder bulk density. Such trends, generally caused by stratification of fines and larger granules during transport/bulk handling, cause fill weights to increase/decrease pro-rata. This trend data can be fed back to the filling head for automatic compensation by increasing or decreasing the number of auger revolutions.

When filling small fill weights such as oral dry suspensions into glass bottles, the weight variation from one bottle to another can slightly differ. If 100% nett weight validation is required, a volumetric fill can be combined with Tare and Gross weighing. Two weigh-cells are integrated within the machine; one to tare weigh the empty bottle, the other to weigh the filled bottle. The tare weight is then deducted from the gross weight to determine the nett weight.

A fill-by-weight filling machine may be selected for a number of different reasons including inconsistency of tare weight, criticality of the fill weight, product density inconsistencies, cost of product give-away and the need to validate the actual fill weight filled.

Filling machines incorporating load cells or balances are available in numerous configurations, but they all use three main modes of controlling the fill weight:

Setpoint (dynamic weighing) – the auger runs at a single speed and the load cell weighs the live fill weight. Filling will stop when the pre-set Setpoint weight is reached. The resultant fill weight will be the Setpoint weight plus any inflight material.

Bulk and Dribble (dynamic weighing) – the auger runs at a high speed for the majority of the fill (bulk) and then slows down to a dribble speed for the remainder. The load cell monitors the live fill weight and provides the signal for the dribble fill to stop.

Bulk and Feed Forward (static weighing) – the auger runs at a high speed for the majority of the fill (bulk) but is stopped just short of the target fill weight. The load cell takes a static weight and the required top-up fill is calculated and converted into a volumetric fill. Although the top-up fill is volumetric, an overall accuracy of ±0.2% is achievable.

In a single head system, a single weigh-cell placed directly under the filling head can be used in exactly the same way as when filling semi-automatically; “single shot”, “bulk and dribble”, and “bulk, predict and top-up”. The weigh-cell can tare weigh the empty container and provide weight data as required. If the reaction/settling time of the weigh-cell prohibitively restricts the production output, moving the weigh-cell downstream and filling volumetrically with feedback may be considered, with upstream tare weigh-cell as required.

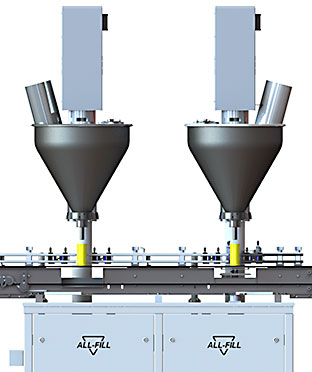

Alternatively, two filling heads could be used, but instead of the two heads dosing onto two live weigh-cells to double the output, a bulk and top-up system could be preferred. This provides the optimum of speed and accuracy, the volumetric first head bulk filling quickly with a large auger, the second head making the gravimetric top-up fill with a more accurate smaller auger. Furthermore, the cost of one weigh-cell is saved.

For even greater speed and accuracy, the weigh-cell can be moved between the two filling heads, turning it into a bulk fill, predict forward and top-up system with intermediate weighing. This offers the speed of a large auger bulk fill together with the accuracy of filling the top-up with a smaller auger, but without the loss of cycle time when filling and weighing sequentially. In this case, the weigh-cell would feed back to the bulk filling head to maintain the proportion of the bulk fill, feed forward to the top-up head, and predict the top-up dose needed, all three functions occurring concurrently. It could not however provide final weight data. If required, a second weigh cell downstream of the top-up head could feed back to the top-up head, and forward to any reject station. If the containers vary in their empty (tare) weight, a tare weigh station would be added upstream of the bulk filling head.